What GroundControl users actually want

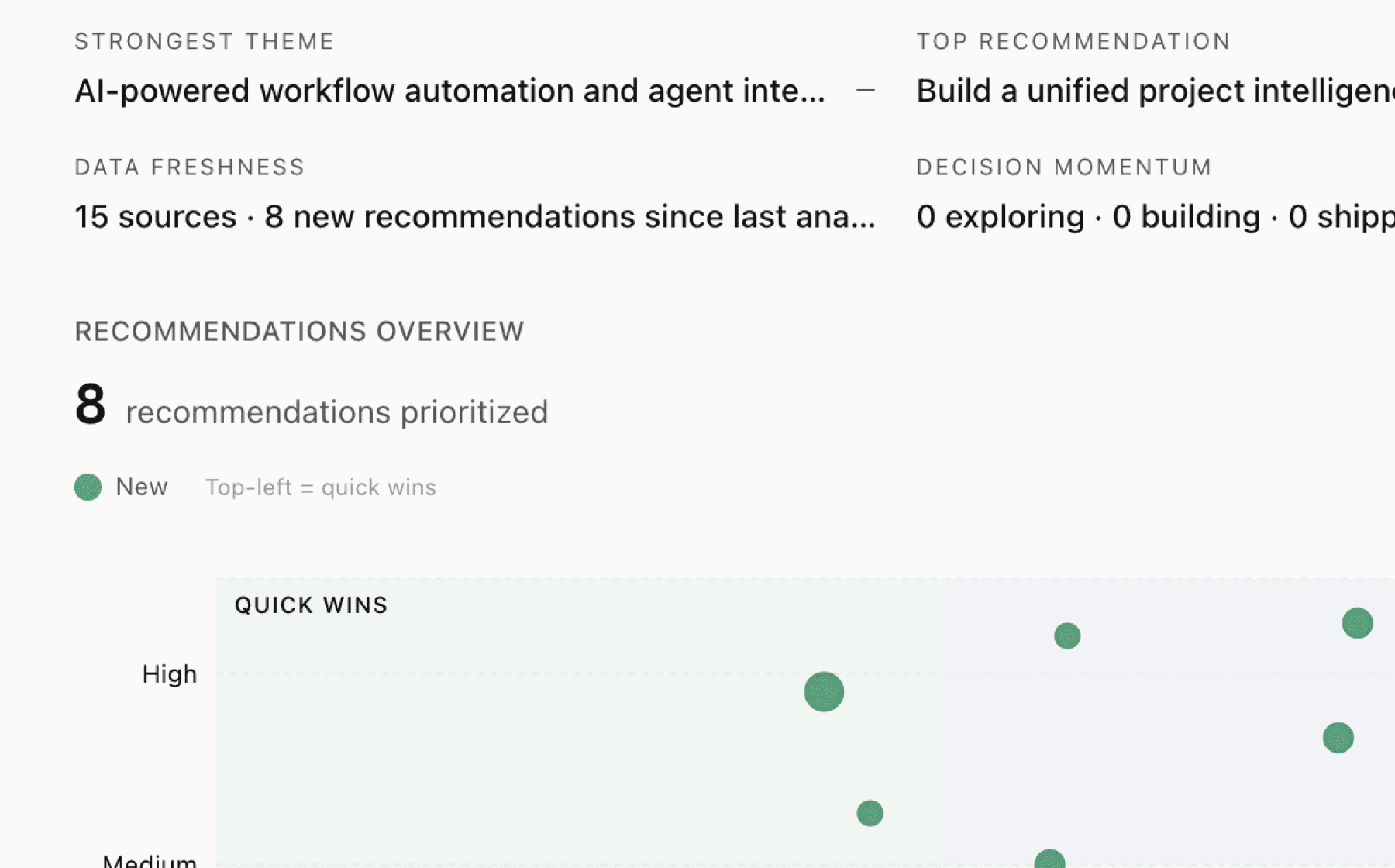

Mimir analyzed 15 public sources — app reviews, Reddit threads, forum posts — and surfaced 15 patterns with 8 actionable recommendations.

This is a preview. Mimir does this with your customer interviews, support tickets, and analytics in under 60 seconds.

Top recommendation

AI-generated, ranked by impact and evidence strength

Build automated CMM-to-FAIR pipeline with live tolerance validation

High impact · Medium effort

Rationale

GroundControl has proven its core value proposition: customers report 50-70% faster FAI cycles, one-month backlog clearance, and operators spending meaningfully more time inspecting parts rather than managing spreadsheets. The 46-source demand signal for automated document generation is the strongest in the dataset and directly drives the primary retention metric — users stay because the tool removes a critical bottleneck blocking revenue.

The next evolution is real-time tolerance enforcement during measurement. Currently, CMM results import after inspection completes, requiring manual reconciliation when values fall out of spec. By validating measurements against drawing tolerances as operators record them, the system can flag non-conformances immediately, prevent batch rejection, and reduce rework cycles. This tightens the feedback loop from hours to seconds and compounds time savings.

This builds on existing CMM integration (PC-DMIS, Calypso, Verisurf) and auto-balloon capabilities. The technical foundation exists — the recommendation is to close the loop by making tolerance interpretation active during data entry rather than passive during export. Evidence shows users value "audit-ready FAIR packages on the first attempt" and want software that "eliminates manual data re-entry" — live validation delivers both.

Projected impact

The full product behind this analysis

Mimir doesn't just analyze — it's a complete product management workflow from feedback to shipped feature.

Evidence-backed insights

Every insight traces back to real customer signals. No hunches, no guesses.

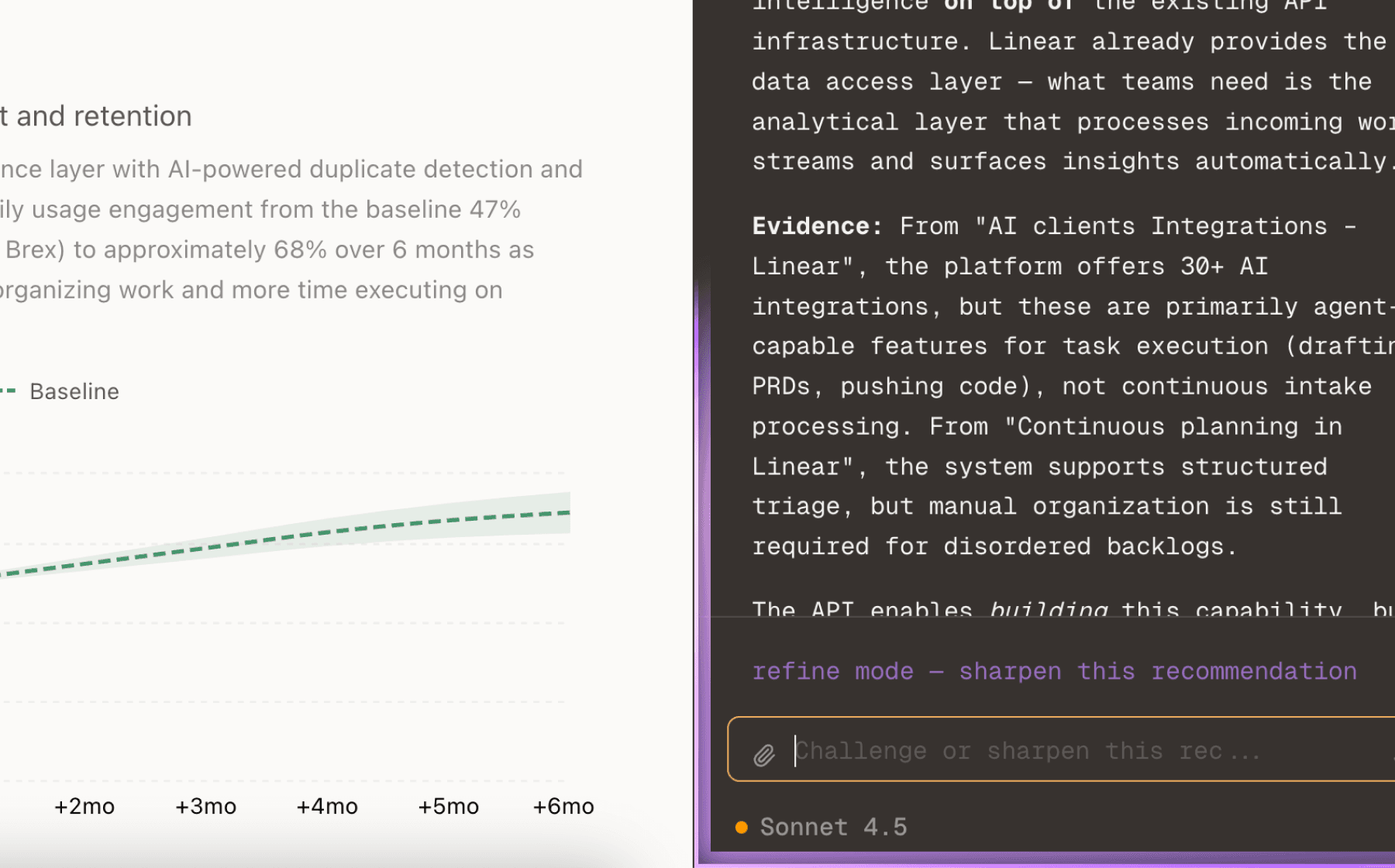

Chat with your data

Ask follow-up questions, refine recommendations, and capture business context through natural conversation.

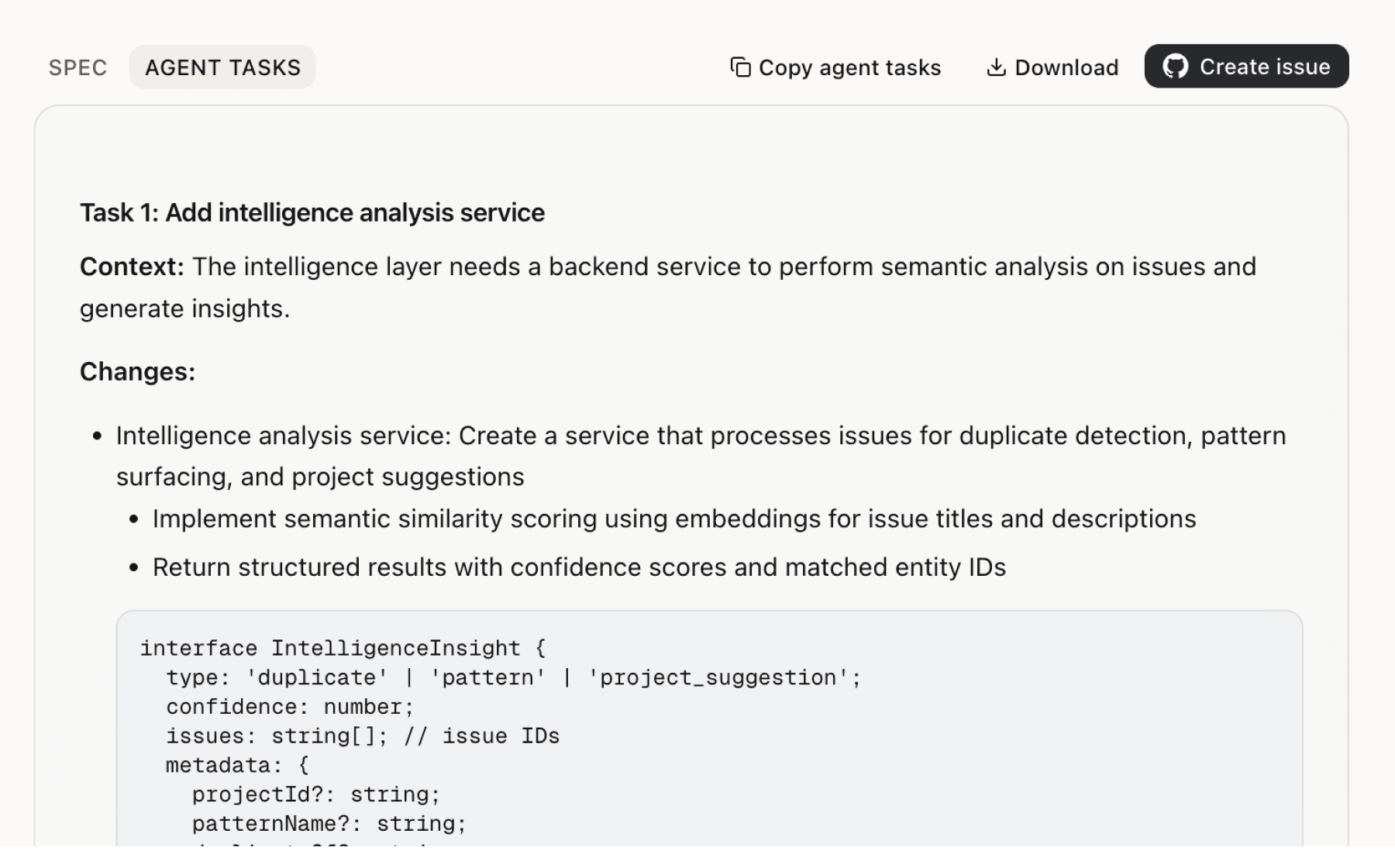

Specs your agents can ship

Go from insight to implementation spec to code-ready tasks in one click.

This analysis used public data only. Imagine what Mimir finds with your customer interviews and product analytics.

Try with your dataMore recommendations

7 additional recommendations generated from the same analysis

The unified quality platform (Theme 2) eliminates data fragmentation, but users need proactive intelligence, not just centralized storage. Multiple sources reference "automatic supplier performance tracking with scorecards" and the ability to "reduce repeat escapes" through tighter closed-loop processes. The opportunity is to surface patterns before they become quality escapes.

AS9100 and CMMC 2.0 compliance are table stakes for the target market, but enforcement happens at audit time rather than during daily work. Users reference "CMMC 2.0 enforcement is rolling out through 2025 and beyond" and "U.S. manufacturers serving DoD must achieve CMMC certification to handle CUI." The regulatory pressure is intensifying, but the product currently treats compliance as a deployment concern (Government Cloud, ITAR handling) rather than a workflow feature.

Quality teams waste time on "endless email chains for quality documentation validation" and manual coordination to collect FAIs, PPAPs, and material certs from suppliers. The 15-source signal for unified traceability shows users need centralized data, but the current model assumes all uploads happen inside GroundControl by internal users. Suppliers are locked out of the system and forced into email-driven workflows that create gaps and delays.

Users complete full operator onboarding in 30 minutes and report meaningful time savings within 1-3 inspection cycles, but the recommendation is to compress time-to-value even further. Current onboarding likely walks through features sequentially (setup, balloon, CMM import, export), which delays the dopamine hit users need to internalize the product's value. The goal is to surface a quick win before users finish their first session.

Users reference "create FAIs directly from 2D drawings and PDFs with organized revision management," but the system likely treats each revision as an independent snapshot. Manufacturing reality is iterative — parts evolve through ECOs, and quality teams must verify that updated drawings don't introduce new non-conformances or invalidate prior inspection work. Without automated comparison, engineers manually red-line changes or rely on memory, which is slow and error-prone.

VisitorControl handles facility access, sanctions screening, and NDA signing for CMMC 2.0 compliance, but the 13-source theme suggests it operates as a standalone module. When audit season arrives, quality teams must manually reconcile visitor logs with production floor access, CUI exposure windows, and foreign national movement — all of which are CMMC control requirements.

GroundControl's cloud deployment and CMM integration eliminate desktop software and server overhead, but data entry still happens at a workstation rather than at the point of measurement. Operators walk from CMM to desk to log results, which introduces friction and context-switching. The opportunity is to close the physical gap between measurement and documentation.

Insights

Themes and patterns synthesized from customer feedback

GroundControl's VisitorControl system replaces unreliable paper logging with digital check-in (QR codes, mobile workflows), badge generation, sanctions screening against multiple lists, and NDA/paperwork signing with retention. This streamlines CMMC 2.0 compliance documentation and improves facility security impressions.

“VisitorControl is a visitor management system designed specifically for manufacturing facilities with compliance needs like CMMC 2.0 and AS9100”

GroundControl provides automatic revision tracking with visibility into what changed, why, and what requires re-approval, along with real-time readiness indicators showing completion status and approval blockers. This streamlines APQP and PPAP workflows and prevents stalled submissions.

“Automatic revision and evidence tracking with visibility into what changed, why it changed, and what needs re-approval.”

GroundControl supports FAI, in-process, WIP/DIP, and final inspection stages in a single platform with centralized results tracking and visibility into all open issues available in seconds. This provides clarity across the complete inspection lifecycle.

“Resolution status visibility across all open issues available in seconds”

GroundControl's 100% cloud deployment requires no hardware, servers, or IT infrastructure setup, enabling full configuration in 30 minutes and new operator onboarding in the same timeframe with minimal training. Weekly automated updates and intuitive UI drive adoption and reduce operational overhead for engineering teams.

“AdvancedPCB case study shows new operator onboarding achieved in 30 minutes with GroundControl”

GroundControl recognizes and applies complex tolerances (bilateral, GD&T, limits, unilateral) directly from drawings per ASME Y14.5, eliminating manual misinterpretation and the error-prone manual connection between drawing specifications, characteristics, tolerances, and results. This reduces quality escapes and speeds the drawing-to-inspection workflow.

“Automatically recognize and apply tolerances (bilateral, GD&T, limits, etc.)”

GroundControl enables standardized FAI and SCAR workflows with searchable audit trails, evidence attachment, and organizational memory for quality improvements, enabling teams to contain, resolve, and prevent issues faster while reducing repeat escapes. This supports compliance audits and creates accountability across quality processes.

“Standardized corrective action process allows issues to be contained, resolved, and prevented faster”

GroundControl validates entries to prevent typos, missing fields, out-of-tolerance measurements, and automatically validates incoming supplier documentation with accurate tolerance and GD&T application. This reduces manual review burden and prevents data quality escapes.

“Error validation to prevent typos, missing fields, and out-of-tolerance measurements in FAI forms.”

GroundControl supports export to AS9102C, Net-Inspect, AIAG-compliant PPAP, OEM-specific templates, and Excel, eliminating manual reformatting and data re-entry when delivering to customers or downstream systems. This reduces friction in approval cycles and accommodates diverse customer requirements without rework.

“Software supports multiple export formats including AS9102C, Net-Inspect, in-process, and customer-specific templates”

GroundControl replaces scattered email and spreadsheet-based supplier communication with a single platform where suppliers can submit work, receive feedback, and close loops while maintaining automatic performance scorecards, trend analysis, and risk visibility. This enables dynamic incoming inspection adjustments and standardized accountability.

“Real-time supplier collaboration keeps requirements, evidence, and approvals out of email”

Users face significant risk of losing historical inspection data and disrupting programs when switching quality management software. Secure migration and preservation of years of FAI records is a critical adoption barrier that must be addressed.

“Switching quality management software risks losing historical inspection data, disrupting programs, and recreating years of FAI reports”

By eliminating inspection backlogs, streamlining FAI/PPAP workflows, and automating compliance documentation, GroundControl enables manufacturers to launch products and ship on time consistently. This directly impacts revenue and customer satisfaction for operations-focused leaders.

“GroundControl enables assembly shops to ship on time consistently”

GroundControl automatically extracts characteristics from drawings, auto-balloons PDFs, and integrates CMM equipment data (PC-DMIS, Calypso, Verisurf) to generate AS9102 forms and FAIRs, eliminating weeks of manual transcription and reducing documentation time to hours or minutes. This directly accelerates inspection cycles, enables operators to focus on actual measurement rather than data entry, and removes a critical bottleneck blocking product launches.

“Auto-balloon 2D PDFs including hand-drawn and scanned prints for FAI documentation.”

GroundControl is purpose-built for aerospace, defense, and regulated manufacturing with native support for AS9100D, AS9102C, CMMC 2.0, ITAR/CUI handling on Government Cloud, and granular requirement traceability with automatic audit trails and evidence attachment. Compliance is embedded in workflows rather than bolted on, enabling organizations to maintain certifications without manual workarounds.

“Desktop FAI tools require constant installations, server costs, and slow upgrade cycles”

GroundControl consolidates supplier quality documents, FAIs, PPAPs, material certificates, inspection records, and CMM results in a single platform with complete traceability from requirements through measurements to final reports. This eliminates data fragmentation across spreadsheets, emails, and disconnected tools, preventing missed characteristics, clerical defects, and quality escapes while creating visibility for immediate detection of missing or non-approved deliverables.

“GroundControl centralizes supplier documents and quality history (FAIs, PPAPs, material certs, inspections, SCARs) with full traceability”

GroundControl cuts FAI times by 50-70%, enables operator onboarding in 30 minutes, and eliminates inspection backlogs through automation of manual transcription, tolerance interpretation, and data reconciliation. These gains directly remove production delays and unlock revenue by clearing the critical path in manufacturing operations.

“Software amplifies user expertise by removing transcription friction and improving traceability”

Run this analysis on your own data

Upload feedback, interviews, or metrics. Get results like these in under 60 seconds.