What Jiga users actually want

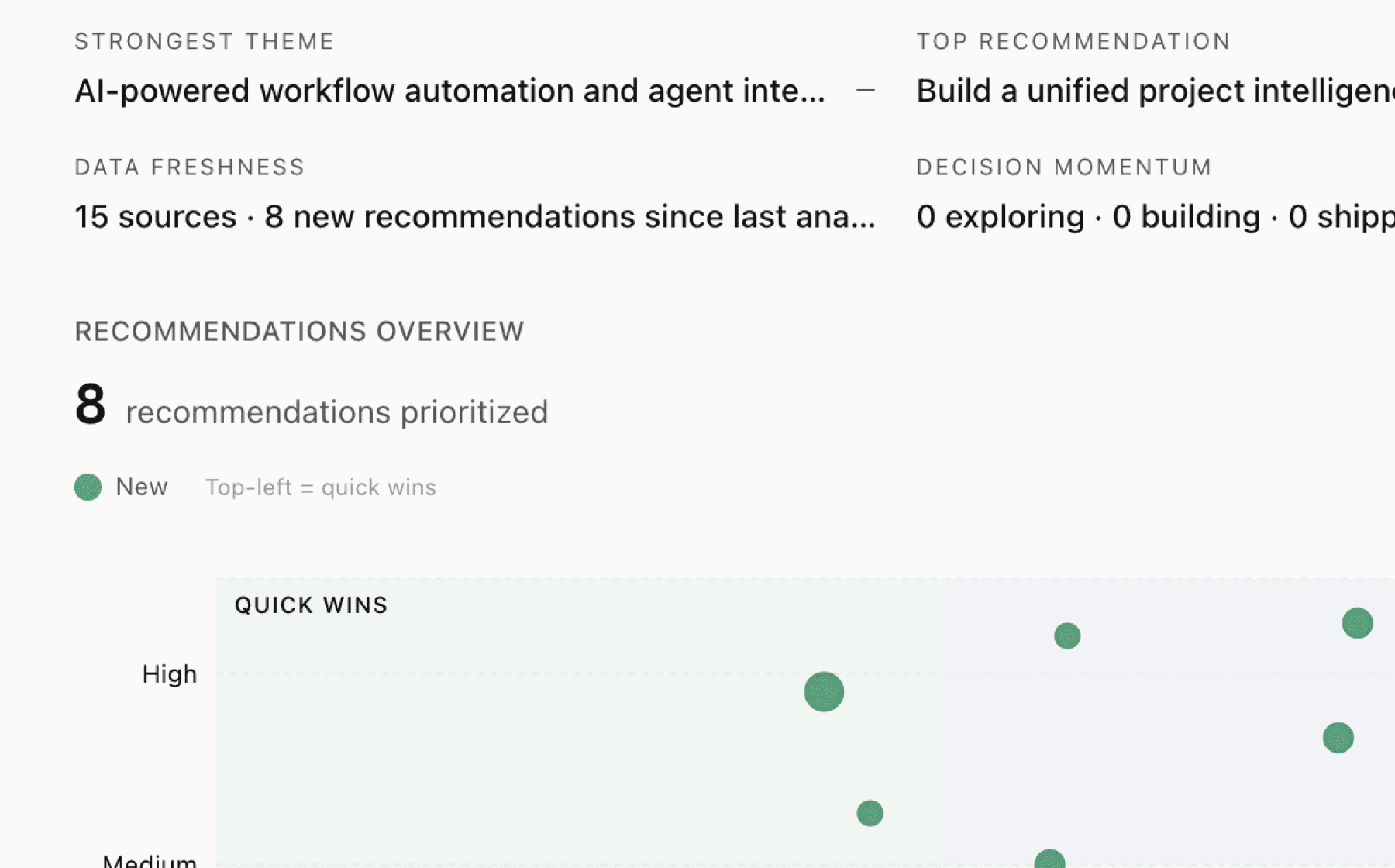

Mimir analyzed 15 public sources — app reviews, Reddit threads, forum posts — and surfaced 15 patterns with 8 actionable recommendations.

This is a preview. Mimir does this with your customer interviews, support tickets, and analytics in under 60 seconds.

Top recommendation

AI-generated, ranked by impact and evidence strength

Build a unified communication dashboard that surfaces critical RFQ status, pending supplier responses, and team actions in one view

High impact · Medium effort

Rationale

Scattered communication across email, spreadsheets, and multiple vendor channels represents the core friction blocking adoption and slowing procurement cycles. 33 sources emphasize this as the primary pain point, with users explicitly stating they don't want to chase email threads and maintain quote spreadsheets. While Jiga consolidates communication, users still need to navigate the platform to find information.

A centralized dashboard that aggregates all active RFQs, highlights pending supplier responses, flags overdue items, and shows team member actions would eliminate the need to search through threads. This directly addresses the stated user need for visibility and tracking while reducing cognitive load.

This recommendation aligns with the business goal of increasing engagement by making the platform the default workspace rather than a tool users check periodically. A dashboard that shows real-time status would pull users into the platform multiple times per day and demonstrate immediate value in the first 30 seconds of each session.

Projected impact

The full product behind this analysis

Mimir doesn't just analyze — it's a complete product management workflow from feedback to shipped feature.

Evidence-backed insights

Every insight traces back to real customer signals. No hunches, no guesses.

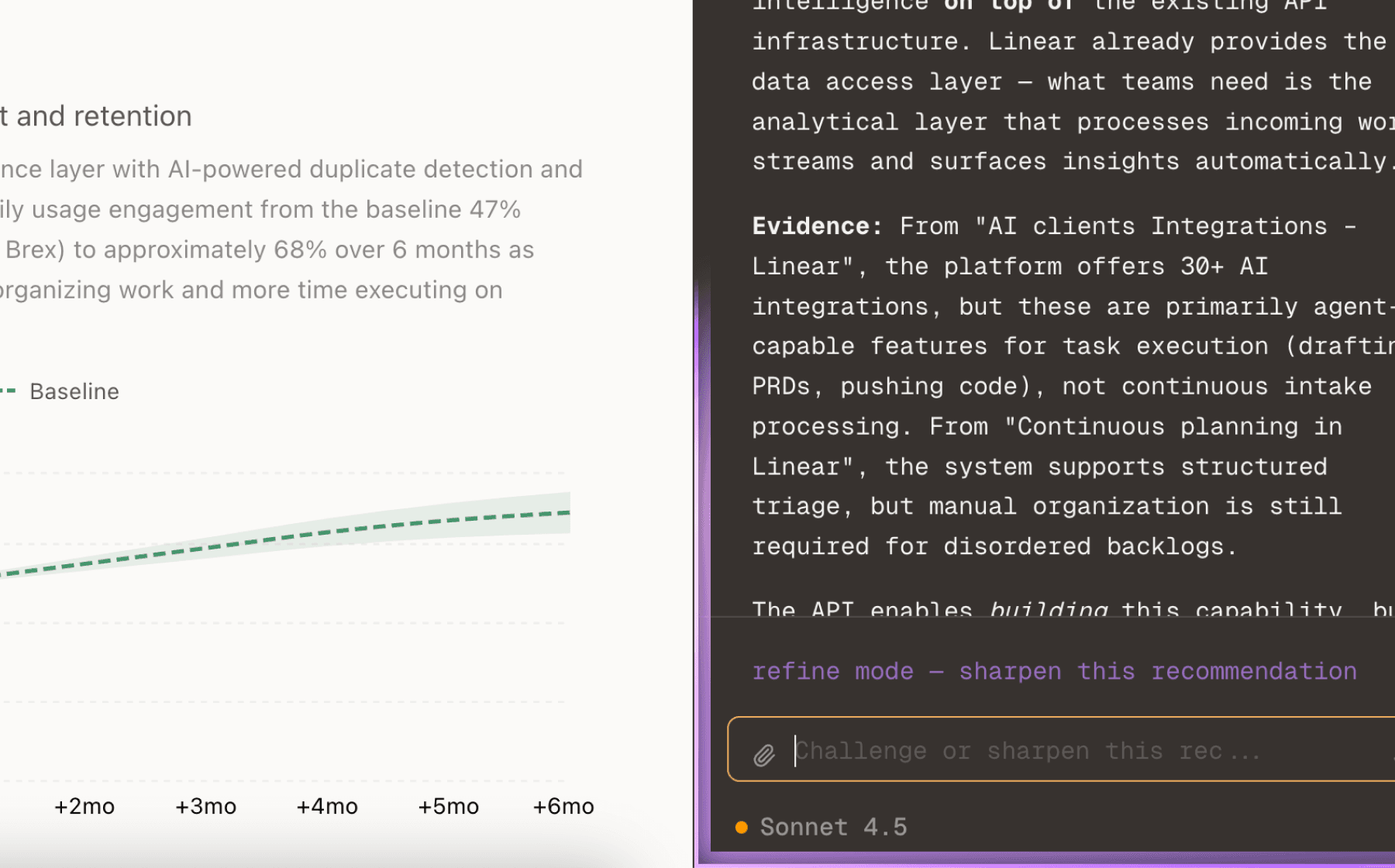

Chat with your data

Ask follow-up questions, refine recommendations, and capture business context through natural conversation.

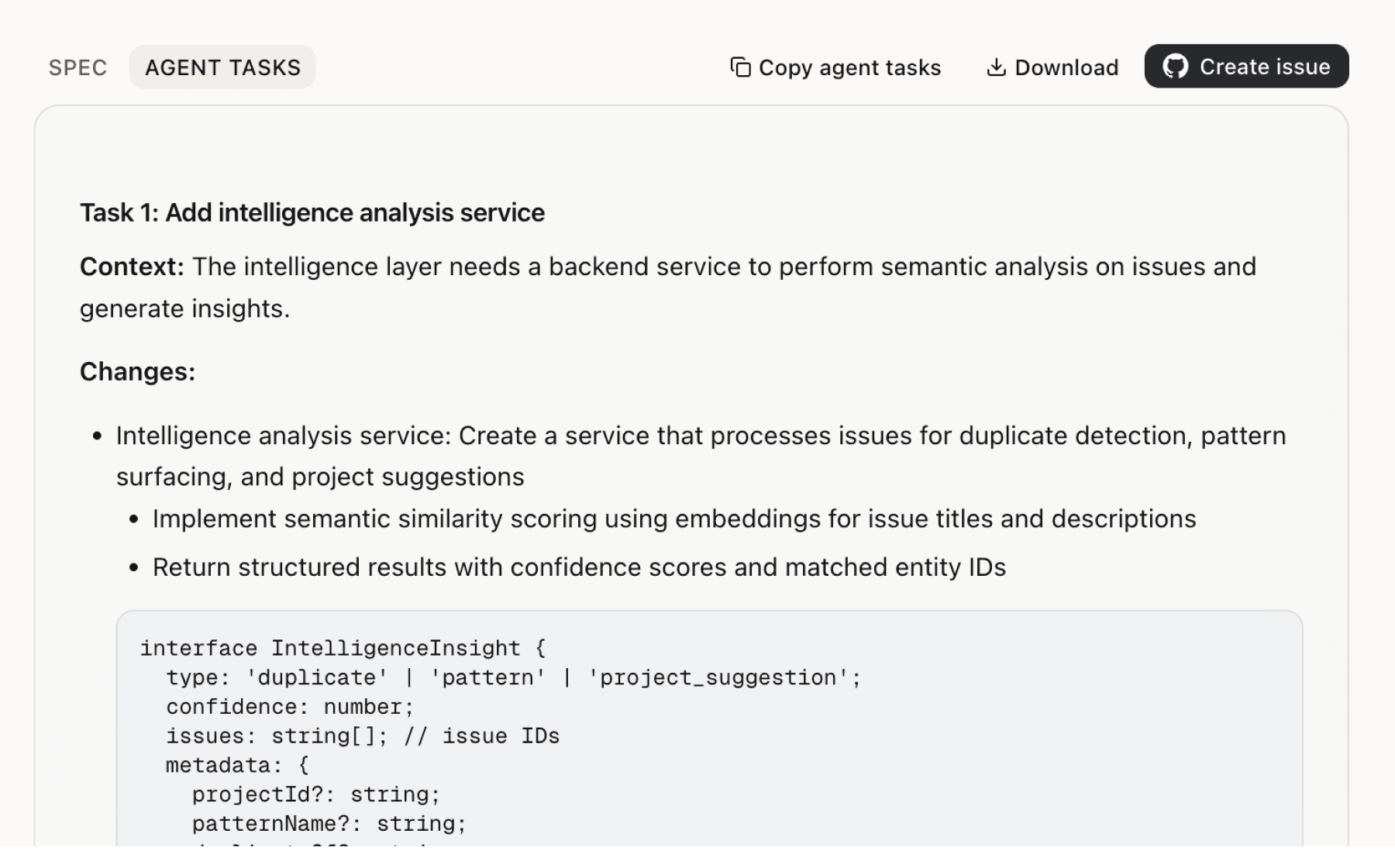

Specs your agents can ship

Go from insight to implementation spec to code-ready tasks in one click.

This analysis used public data only. Imagine what Mimir finds with your customer interviews and product analytics.

Try with your dataMore recommendations

7 additional recommendations generated from the same analysis

Users consistently achieve 20% cost reductions and actively expand sourcing to capture more savings, but the platform doesn't systematically surface this value. 15 sources document cost reduction as a primary driver of retention and expansion. Users need quantified proof of savings to justify continued investment and expand adoption within their organizations.

Direct supplier communication creates ownership and speeds procurement cycles, but users lack visibility into when suppliers fall short of expected response times. 12 sources highlight responsiveness as critical to cycle time reduction, and the data shows Jiga customers achieve measurable lead time and PO cycle time reductions. However, accountability depends on transparent performance tracking.

Users need transparent, metrics-based supplier evaluation to replace subjective decision-making. 11 sources document the gap between current gut-feel approaches and the standardized metrics required for manufacturing efficiency. While Jiga conducts rigorous supplier vetting and quality control, buyers lack visibility into comparative supplier performance when selecting vendors for new RFQs.

Jiga provides access to diverse manufacturing capabilities across CNC machining, injection molding, sheet metal, 3D printing, and welding with extensive material options, but users face decision paralysis when choosing between processes and materials. 8 sources highlight this breadth as a strength, yet the platform doesn't guide users toward optimal choices for their specific needs.

Tier-1 customers like NASA, Tesla, and Siemens provide strong social proof, and documented case studies exist, but the evidence doesn't systematically quantify business impact in ways that support account expansion or new customer acquisition. 6 sources document market validation through established customers and testimonials, yet users need concrete data to justify expanding Jiga usage beyond initial pilot projects.

Jiga collects comprehensive personal and usage data with third-party sharing, cross-border transfers, and limited user opt-out options, creating regulatory and trust risks for enterprise customers. 11 sources document data security and privacy concerns, including the acknowledgment that no internet transmission is 100% secure and that Jiga cooperates fully with law enforcement requests.

Jiga's supplier value proposition includes reducing administrative burden, transparent relationships, and reliable payment terms, but suppliers lack visibility into their order pipeline and payment status. 7 sources document the importance of the supplier ecosystem to buyer success through increased competition and choice, yet suppliers face logistics and invoicing complexity that creates overhead.

Insights

Themes and patterns synthesized from customer feedback

Trusted adoption by tier-1 companies like NASA, Tesla, and Siemens, plus documented case studies and customer testimonials from companies like Humotech and Global Formula Racing, demonstrate product-market fit and provide social proof for new customer acquisition.

“Jiga is trusted by world's top-tier companies including NASA, Tesla, and Siemens for injection molding services”

Jiga actively expands with specialized services (welding, LLM integration), aerospace/defense focus, and broader manufacturing process coverage. Continuous development indicates commitment to addressing emerging customer needs and market segments.

“Jiga maintains an active sitemap with content spanning manufacturing processes (CNC, sheet metal, injection molding, FDM), customer case studies (NASA, Tesla, Siemens), and platform features...”

Jiga streamlines overseas vendor interactions by simplifying payment and eliminating international transaction complexity, reducing administrative overhead for global sourcing operations.

“Jiga's platform simplifies payment and eliminates hassle of dealing with international transactions”

Jiga's free platform access with payment only on sourced parts removes barriers to trial, allowing users to experience centralized quoting, team collaboration, and supplier communication before financial commitment. This addresses user adoption friction.

“Jiga operates on a freemium model: free to use with payment only for sourced parts”

While Jiga enables collaboration, users request enhanced support for all CAD formats, 2D GD&T drawings, and email integration notifications. These gaps limit comprehensive design collaboration and accessibility for some workflows.

“Platform should support all CAD formats and 2D GD&T drawings for comprehensive design collaboration”

NDAs and terms protecting proprietary information ensure suppliers comply with confidentiality standards, maintaining trust and integrity within the Jiga ecosystem.

“Suppliers must sign NDAs and agree to terms and conditions to protect Jiga's trade secrets and proprietary information.”

Jiga's policy of deleting user information without notice once deemed unnecessary may impact data accessibility and compliance. Clearer retention periods and user control mechanisms are needed to align with user expectations.

“Jiga reserves right to delete information from systems without notice once deemed no longer necessary”

Manufacturing efficiency depends on standardized metrics for supplier performance (lead time, responsiveness, cost reduction, stock availability). Jiga enables transparent, metrics-based supplier evaluation across KPIs, replacing gut-feel approaches and automating performance data into company systems for better decision-making.

“Supplier Scorecard should be transparent and work both ways to highlight issues on both sides”

Jiga collects comprehensive personal and usage data with limited user opt-out options. Third-party data sharing, cross-border transfers, and internet security limitations create regulatory and trust risks. Clear communication and robust safeguards are essential to maintain user confidence.

“Personal data is shared with trusted service providers, business partners, affiliates, subcontractors, and suppliers located potentially in different countries”

Jiga provides access to vetted manufacturers across multiple processes (CNC machining, injection molding, sheet metal, 3D printing, welding) with extensive material options, tolerances, and advanced capabilities. This breadth addresses diverse customer manufacturing needs and supports faster design iteration.

“Content strategy includes educational resources (material selection guides, rapid prototyping definition, CNC material guides) and blog content like 'The Forbidden Shop Talk' and 'The AI Box'.”

Jiga's value proposition for manufacturing suppliers—reducing administrative burden, enabling transparency through profile visibility, streamlining logistics and invoicing, and providing reliable payment terms—expands the platform's supplier network. This ecosystem growth benefits buyers through more competition and supplier choice.

“Jiga targets manufacturing suppliers with value proposition of business opportunities, reduced administrative burden, and transparent relationships”

Users struggle with scattered communication across email, spreadsheets, and multiple vendor channels. Jiga consolidates RFQ management, vendor communication, team collaboration, and quote tracking into a single platform, directly reducing manual overhead and enabling faster sourcing cycles. This addresses the core friction point blocking adoption.

“Because you have a direct line of communication with the teams making the parts, there is an added level of ownership that you don't see with other platforms.”

Customers consistently achieve 20% cost reductions through Jiga's platform, and users actively expand sourcing to more parts to capture additional savings. This strong economic value directly correlates with product-market fit and account expansion.

“Supply chain efficiencies are one of the most effective ways to save money while growing and protecting business”

Manufacturing teams need direct access to manufacturers rather than opaque intermediaries. Jiga enables direct communication with production teams, creating ownership, faster response times, and measurably reduced procurement cycle times. This transparency also improves part quality and builds reliable partnerships.

“Lead time is split into supplier lead time (order confirmed to delivery) and vendor lead time (item availability to delivery), measured in days”

Jiga maintains high supplier quality through a 6-step quality control process including on-site audits, continuous performance monitoring, and supplier removal. Combined with quality guarantees (remakes and refunds), certifications, and inspection audits, this assures customers that parts meet specifications and eliminates defective product risk.

“Consistent stream of defective products puts business at risk”

Run this analysis on your own data

Upload feedback, interviews, or metrics. Get results like these in under 60 seconds.